Poultry Feed Plant

125000 INR/Unit

Product Details:

- Frame Type Heavy Duty Steel Frame

- Drive Belt & Chain Drive Combination

- Accuracy 1% Batching

- Cooling System Air / Water Cooling available

- Voltage 380-440V

- Power Rating As per installed machinery

- Lubricating System Centralized Grease Lubrication

- Click to view more

X

Poultry Feed Plant Price And Quantity

- 125000 INR/Unit

- 1 Unit

- Minimal, user-friendly design

- 60-120 rpm (per equipment)

- Emergency Stop, Overload Protection, Safety Guards

- Low (Optimized for continuous production)

- Provided by Manufacturer

- Maize, Soybean, Grains, Additives, Feed Grade Minerals

- 1-2 Persons per shift

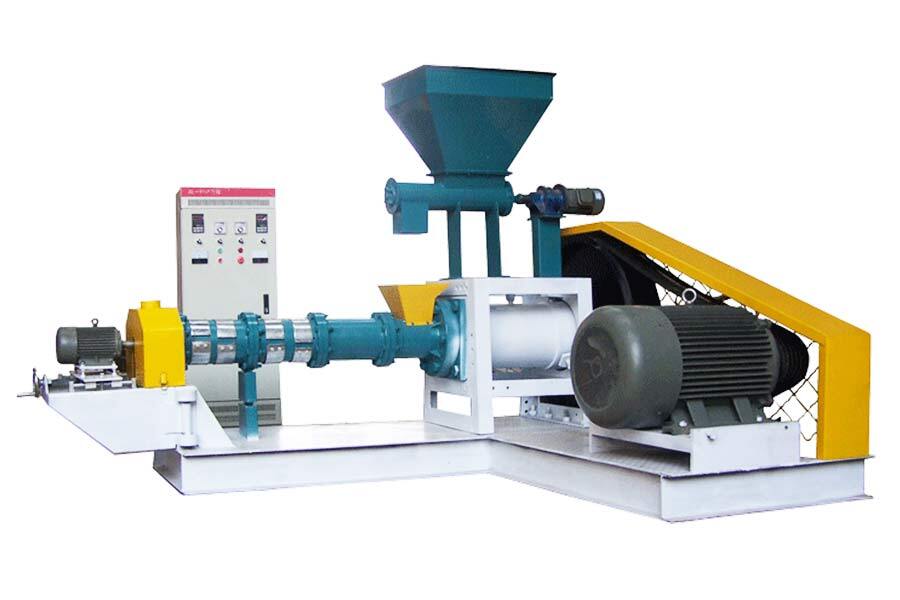

- Feed Mixer, Grinder, Pellet Mill, Conveyor Belts, Feed Cooler, Packing Unit

- Fully Automatic

Poultry Feed Plant Product Specifications

- 50-150 HP (variable as per capacity)

- Electric

- Optional SCADA/Remote Monitoring

- 1-10 TPH

- Customized / As per plant layout

- PLC Automated Control Panel

- < 85 dB

- Automatic, Robust design, Energy efficient, Easy maintenance

- PFPL-1032

- Ambient to 45C

- Poultry Feed Pellet Production Line

- 50-60 Hz

- Approx. 2000-6000

- 20-75 HP (Unit Variable)

- 380-440V

- As per installed machinery

- Blue & White

- Poultry Feed Plant

- Centralized Grease Lubrication

- Automatic

- Standard Atmospheric

- Automatic

- Heavy Duty Steel Frame

- Powder Coated

- Belt & Chain Drive Combination

- 1% Batching

- Air / Water Cooling available

- Production of poultry feed for chickens, ducks, etc.

- Minimal, user-friendly design

- 60-120 rpm (per equipment)

- Emergency Stop, Overload Protection, Safety Guards

- Low (Optimized for continuous production)

- Provided by Manufacturer

- Maize, Soybean, Grains, Additives, Feed Grade Minerals

- 1-2 Persons per shift

- Feed Mixer, Grinder, Pellet Mill, Conveyor Belts, Feed Cooler, Packing Unit

- Fully Automatic

Poultry Feed Plant Trade Information

- All India

Product Description

| Material | MS |

| Motor Power | 10 hp |

| Automation Grade | Semi Automatic |

| Capacity | 500 kg per hr |

| Country of Origin | Made in India |

| Brand | Rising Industries |

| Voltage | 440 VOLT |

| Warranty | 1 YER |

| Type of Machine | Poultry Feed Plant |

We are holding rich experience in the domain of manufacturing and exporting a quality range of Poultry Feed Making Machine. This equipment is manufactured in compliance with set industrial norms, using best quality materials and components. This equipment consumes less power and high operational fluency. We make this Poultry Feed Making Machine available for clients in different technical specifications as per their requirements. Also, we offer this equipment at cost effective prices.

Features:

-

Rugged design

-

Easy to install

-

Maintenance free

Advanced Automation & Control

The plant features a fully automatic operational model, managed by a PLC automated control panel for precise batching accuracy (1%) and seamless integration of all equipment. Optional SCADA and remote monitoring provide advanced supervision, making the system highly efficient and reducing operator involvement to just 1-2 persons per shift.

Comprehensive Raw Material Compatibility

Engineered to process maize, soybean, various grains, feed grade minerals, and additives, the plant ensures optimal flexibility in poultry feed formulation. This compatibility allows producers to tailor feed mixtures for chickens, ducks, and other poultry, enhancing livestock nutrition and farming productivity.

Safety & User-Friendliness

Designed with emergency stop features, overload protection, safety guards, and a noise level below 85 dB, operator well-being is prioritized. The heavy-duty steel construction, centralized grease lubrication, and powder-coated surface make the plant durable, easy to maintain, and safe for continuous operation.

FAQ's of Poultry Feed Plant:

Q: How does the poultry feed plant handle different types of raw materials?

A: The plant is compatible with a wide array of raw materials, including maize, soybeans, grains, additives, and feed grade minerals. This flexibility allows it to efficiently process various recipes, ensuring tailored nutrition for different poultry species.Q: What is the typical installation and commissioning process for this feed plant?

A: Installation and commissioning are provided by the manufacturer, ensuring that the plant is assembled, adjusted, and tested at your facility. The process is managed by experienced engineers to guarantee optimal system performance from the start.Q: Where can the plant be installed, and are its dimensions customizable?

A: The plant can be installed at any suitable industrial or farm site with the required electrical infrastructure. Its dimensions are fully customizable to fit your available space and specific plant layout requirements.Q: What benefits does the fully automatic system offer for feed production?

A: The automatic system minimizes manual intervention, increases batching accuracy (1%), and supports continuous, efficient feed production. This leads to reduced labor costs, consistent product quality, and improved operational safety.Q: How many operators are required to run this feed pellet production line?

A: Thanks to its automation and user-friendly controls, the plant requires only 1-2 operators per shift for monitoring and general supervision, significantly reducing labor requirements compared to manual systems.Q: What safety features are incorporated in the feed plant design?

A: The plant includes emergency stop buttons, overload protection mechanisms, safety guards, and noise suppression (< 85 dB) to ensure a safe and comfortable working environment for operators.Q: What is the maintenance requirement for the poultry feed plant?

A: Maintenance is minimal due to the centralized grease lubrication system, robust design, and easy-access components. Routine checks and timely lubrication are sufficient to keep the plant running smoothly, ensuring long equipment lifespan.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email