Automatic Cattle Feed Making Machine

125000 INR/Unit

Product Details:

- Frame Type Heavy Duty Mild Steel Frame

- Model No CFM-2458

- Operating Temperature 5C to 45C

- Machine Type Pellet Mill / Cattle Feed Making Machine

- Voltage 220-440V

- Lubricating System Automatic Oil Lubrication

- Frequency 50-60 Hz

- Click to view more

X

Automatic Cattle Feed Making Machine Price And Quantity

- 1 Unit

- 125000 INR/Unit

- Emergency Stop, Overload Protection

- Readily Available

- Automatic Variable Speed Feeder

- 2 mm to 12 mm

- Manual and Automatic Options

- On-Site Installation Available

- Mild Steel with Hardened Rollers and Die

- Available Across India

- High Designed for Continuous Operation

- 1-2 Persons

Automatic Cattle Feed Making Machine Product Specifications

- Automatic Electronic Panel

- 1200 kg (approx.)

- High

- Robust Construction, Low Power Consumption, Uniform Pellet Size, Easy Maintenance

- 15 HP - 50 HP Depending on Capacity

- Low

- 1-2 Tons/Hour

- Blue-Grey

- 2450 x 850 x 1890 mm

- Cattle Feed Production, Poultry & Livestock Feed Preparation

- Gear Drive

- Electric

- Air Cooling

- Paint Coated

- Automatic

- 50-60 Hz

- 10-50 kW (depending on model)

- Automatic Cattle Feed Making Machine

- Automatic Oil Lubrication

- High Pressure

- 220-440V

- 3 Phase, 10-50 kW

- Automatic

- Heavy Duty Mild Steel Frame

- Pellet Mill / Cattle Feed Making Machine

- 5C to 45C

- CFM-2458

- Emergency Stop, Overload Protection

- Readily Available

- Automatic Variable Speed Feeder

- 2 mm to 12 mm

- Manual and Automatic Options

- On-Site Installation Available

- Mild Steel with Hardened Rollers and Die

- Available Across India

- High Designed for Continuous Operation

- 1-2 Persons

Automatic Cattle Feed Making Machine Trade Information

- All India

Product Description

| Material | MS |

| Motor Power | 10 hp |

| Automation Grade | Automatic |

| Capacity | 10 tph |

| Country of Origin | Made in India |

| Brand | RISING |

| Voltage | 440 VOLT |

| Warranty | 1 YER |

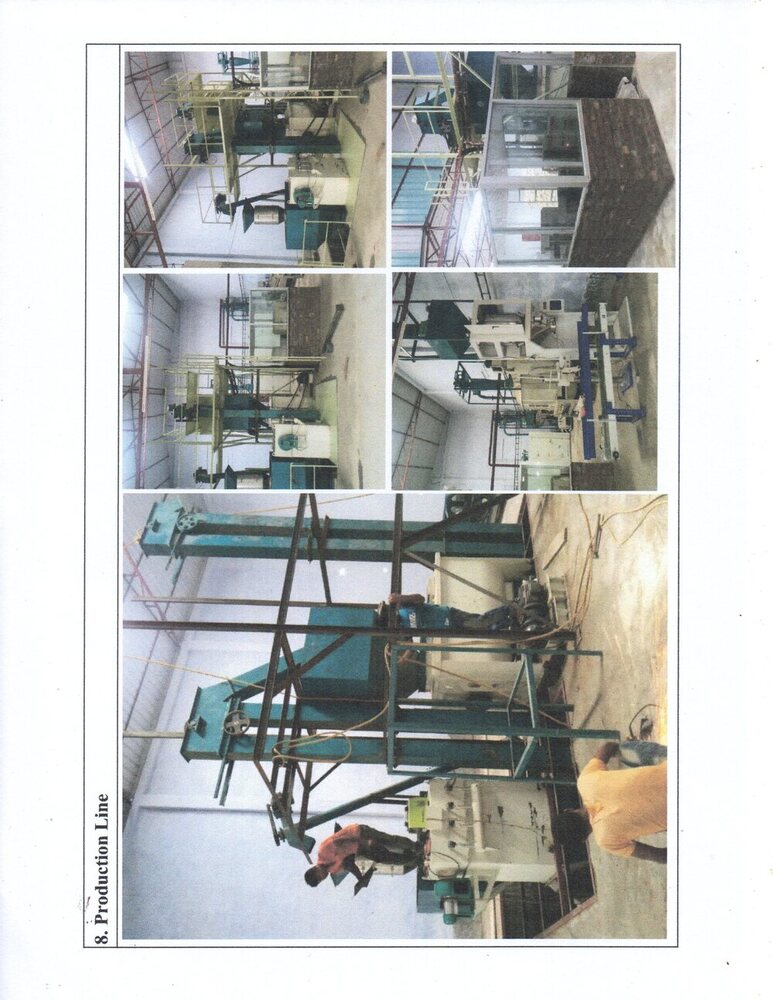

Small Cattle Feed plant are used to manufacture Cattle Feed such as feed for Buffalo, Bulls etc. Main machinery use for this purpose conveyors, grinders, mixer machine, cooler, sieve. This range of quality Cattle Feed Machinery features minimum energy consumption and high capacity. The modular structure of the plant is compact and it requires less investment in civil works. In addition to this, the modular structure is containerized and it assures convenient assembly and dismantle of the machinery.

High-Capacity and Uniform Pellet Output

The Cattle Feed Making Machine boasts a production capacity of 1-2 tons per hour, making it suitable for commercial feed manufacturers. With precise control via its electronic panel, both manual and automatic roller adjustments are possible, ensuring uniform pellet sizes critical for animal nutrition and feed efficiency.

Robust Construction and Durability

Manufactured with a heavy-duty mild steel frame and hardened rollers and die, the machine is built for longevity even under continuous, high-pressure operation. A durable paint-coated surface protects against corrosion, and integrated systems-like automatic lubrication-minimize downtime and maintenance costs.

Comprehensive Support and Safety Assurances

Operators benefit from on-site installation and readily available spare parts throughout India. Safety is prioritized through the inclusion of emergency stop buttons and overload protection, ensuring smooth, risk-mitigated operation for a workforce of just 1-2 persons per shift.

FAQ's of Automatic Cattle Feed Making Machine:

Q: How does the automatic variable speed feeder improve feed production?

A: The automatic variable speed feeder ensures continuous, consistent feed flow into the machine, allowing for precise control over production rates. This optimizes pellet quality and quantity, reducing wastage and accommodating different feed formulas.Q: What is the recommended operating environment for this cattle feed making machine?

A: The machine is designed to operate best within temperatures of 5C to 45C. It requires a stable power supply of 220-440V, three-phase, and can handle frequent use in commercial settings, benefiting from its high energy efficiency and cooling system.Q: Where is installation support and after-sales service available in India?

A: On-site installation support is available throughout India. In addition, service support and spare parts are readily accessible nationwide to ensure uninterrupted machine performance and minimal downtime.Q: What are the benefits of the hardened rollers and die?

A: Hardened rollers and die contribute to machine longevity and produce feed pellets that are uniform in size and structure. This ensures reliable nutrition delivery to cattle and other livestock while reducing operational wear and tear.Q: How many staff are required to operate the machine, and what is the skill level needed?

A: Only 1-2 operators are required due to the machine's automatic technology and user-friendly control panel. Basic machinery operation skills are sufficient, as both manual and automatic adjustments are straightforward.Q: What safety features are integrated into the machine?

A: The machine is equipped with essential safety mechanisms, including an emergency stop button and overload protection, significantly minimizing operational hazards for operators working with high-pressure systems.Q: What maintenance and servicing options are available for this machine?

A: Maintenance is simplified with an automatic oil lubrication system and easy-access service points. Professional servicing and spare parts can be obtained quickly anywhere in India, providing peace of mind to owners and operators.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email